Our product highlights at the fair:

We are known for solutions of the highest technical standard. By ensuring that the processed material is exactly in its intended position, our web guiding systems effectively minimize waste and downtime. Practical: You gain more flexibility with a new, even simpler operating concept. For the first time, the new Commander SMART COM 100 allows the sensor and control unit to be operated from a single control point.

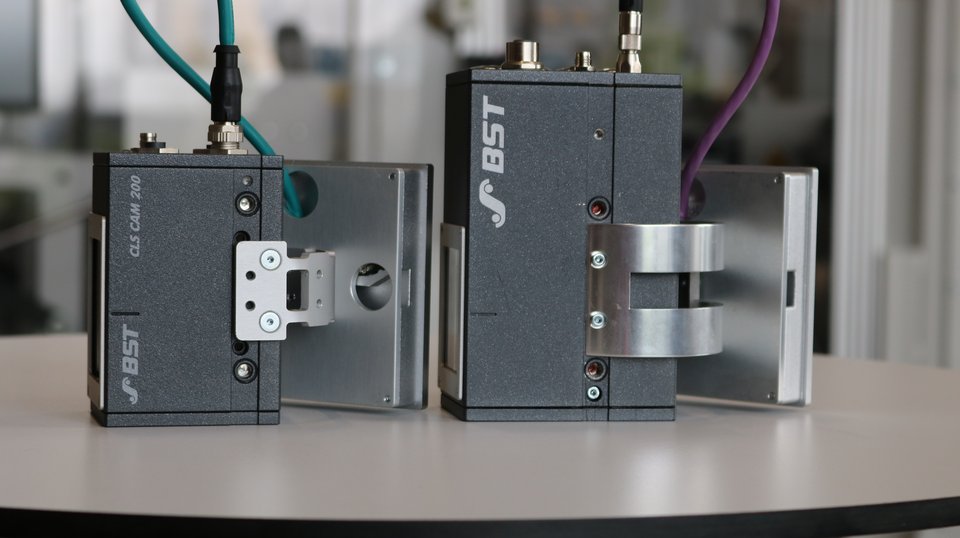

This includes the new ekr CON 610 control unit and the new CLS CAM 200 sensor, which is only half the size of its predecessor, the CLS Pro 600, and enables even better control results thanks to optimized sensor technology.

In addition to these innovations, we will be presenting FRAMEGuide and COMPACTGuide, its reliable and classic web guiding systems. Our web guiding systems can be equipped with interfaces and exchange process data with or via SMARTData, for example.

To provide you with enhanced added value in terms of image quality, sustainability and longevity, we have further developed the iPQ-View high-end video web inspection system, which has been established in the market for many years. The iPQ-View now features cutting-edge CMOS sensor technology, along with energy-efficient, durable high-performance LEDs, and other practical innovations. In addition, the housing size has been significantly reduced to allow more flexibility in difficult installation environments.

The PROView web monitoring system, a comparatively inexpensive and simple solution, will also be on show for the first time at drupa. Even at a maximum web speed of 1,000 meters per minute, it enables reliable print image monitoring.

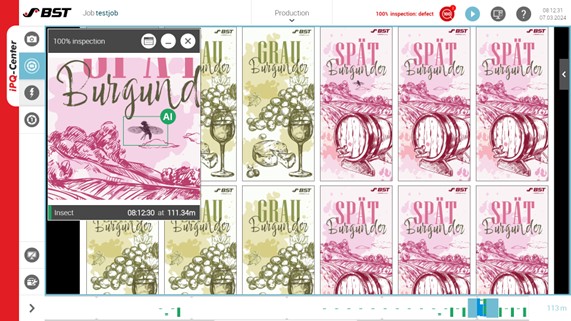

The new iPQ-Check Digital inspection system is used for digital printing systems. Thanks to SMARTData, iPQ-Check Digital is fully integrated into the customer's workflow: Jobs are created in prepress, then loaded into SMARTData Preparation, where data is prepared for and transferred to iPQ-Check Digital to perform the inspection. The digital process enables operator-free job setup, automatic job changeover, full inspection from the first format and job sizes with a quantity of one.

In addition, specific print defects in digital printing can be checked with process-typical defect classes, such as narrow streaks - representative of print nozzle failures - and bending defects.

For even more precise defect classification, both iPQ-Check and iPQ-Check Digital now offer an additional defect class whose data set is generated using artificial intelligence. For example, customer-specific defects or defects with high relevance, such as mosquitoes, can be classified more clearly and make an important contribution to further evaluation.

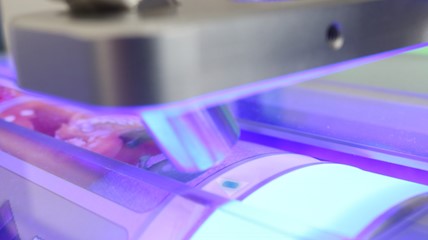

The globally established RSH sensor family of the regi_star 20 will be extended by a new UV sensor at drupa. The new sensor can be used to detect and scan UV coatings in the wavelength spectrum from 370 to 390 nanometers. Handling like a standard sensor, UV coatings can be quickly adjusted and the printing set-up process extremely accelerated. It is possible to adjust both the longitudinal and lateral register. During the production process, it is ensured that the UV coating is permanently in register. All this saves waste, time and costs and contributes to higher quality and greater sustainability.

In addition to regi_star 20, the universally applicable TWINStar register control system will be on show at drupa - the compact system is particularly impressive for controlling trailing printing units, finishing or tool stations and for insetting pre-printed materials.

SMARTData provides the solution to the cross-industry question of how quality in web processing can be further increased, work processes simplified for the user and reporting made even more meaningful. SMARTData adresses these challenges from two sides. On the one hand, job data no longer has to be entered manually for each system, but can be fed centrally into the individual systems directly from the ERP, MIS system or prepress. This saves time and reduces the susceptibility to errors. On the other hand, SMARTData works more intelligently with the data than conventional systems in the industry.

SMARTData is not only able to store the data locally, but can also synchronize it in a database with a modern RESTful API across multiple processes in the form of a digital twin. This means that the process data and quality reports supplied are far more accurate, providing the ideal basis for precisely controlling and eliminating errors and avoiding them in the future. Equipped with a SMARTData interface, an unlimited number of BST systems can be integrated accordingly.

Further questions

If you have any general questions about the trade fair, please do not hesitate to contact us! You can contact us directly at: marketing@bst.group.

We look forward to answering your questions and providing you with further assistance.